Coating Ultra-Large Plates: Expert Tips and Techniques

I’m often asked whether coating ultra-large plates, like the impressive 20×24-inch pieces, is significantly harder than working with smaller ones. The answer? Both yes and no.

When you move up to this scale, every step of the process demands greater precision, patience, and practice. Spreading emulsion evenly across such a vast surface isn’t as straightforward as it sounds. Using a syringe coating technique, for instance, often means stopping to refill your emulsion cup three or four times while keeping the plate perfectly level to prevent spills.

The weight of a large glass plate can actually help stabilize it with your fingers, as long as it isn’t excessively heavy. But the stakes are higher, one small slip or spill can mean losing a significant amount of material, time, and effort.

The Challenges of Coating Ultra-Large Plates

Working on large-format plates introduces its own unique hurdles:

Precision and Practice: Achieving an even emulsion layer across a 20×24-inch surface takes a lot of skill and muscle memory.

Multiple Refills: With syringe coating, you’ll likely need to refill your emulsion cup several times, each refill being a moment of potential risk.

Managing Spills: A spill at this scale isn’t a minor inconvenience; it’s a costly setback in both materials and work hours

Expert Tips for Success

Here are some valuable tips I’ve learned for coating large plates efficiently and cleanly:

Use Thicker Glass: For any plate larger than 8×10 inches, choose glass that’s at least 3 mm thick. The added rigidity helps prevent flexing during coating.

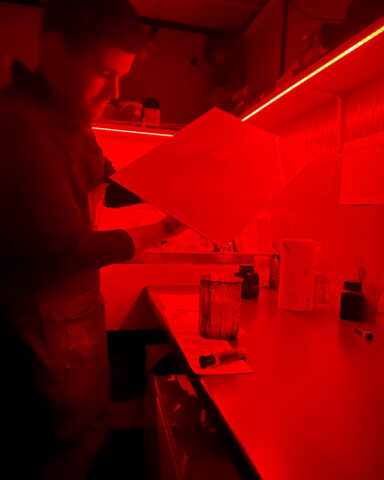

Choose the Right Drying Space: Work in a dark, well-ventilated area. A dedicated drying cabinet, or even a carefully set-up counter in your darkroom, can make a world of difference.

Protect Your Workspace: Spills are almost inevitable, so cover your work surface with newspapers or protective sheets to simplify cleanup.

Prepare in Advance: Melt plenty of emulsion before you start. Running out halfway through can break your rhythm and lead to uneven coverage.

Select the Right Syringe: I usually work with a 20 ml syringe. Larger syringes mean fewer refills, but they’re also harder to control precisely.

Keep Everything Warm: Maintain warmth in both the workspace and the plate. A hairdryer or heating pad can help keep the emulsion fluid and prevent it from setting too early on one side.

Stay Focused: Once you start coating, work swiftly and methodically. There’s little room for hesitation, momentum and focus are your best tools.

Pushing the Boundaries: Beyond Hand-Coating

From my experience, 20×24 inches is about the upper limit for hand-coating. Beyond that, things get exponentially more complex. For even larger formats, alternative solutions might be necessary, such as placing the plate over one or more dish-tray heaters to keep it warm during the process.

That said, this approach introduces new challenges: maintaining a perfectly level surface and managing the flow of excess emulsion becomes increasingly demanding.

Final Thoughts

If you’re eager to experiment with ultra-large plates, start smaller and work your way up. Every attempt, even the costly mistakes, teaches you something essential about the balance of timing, temperature, and technique.

Remember, the art of coating isn’t limited to the act itself. It also involves careful planning around drying, storage, and exposure.

Mastering ultra-large plate coating is a rewarding blend of technical skill, creative problem-solving, and persistence. With patience and practice, you’ll be able to achieve beautifully even coatings on even the most ambitious surfaces.

If you’d rather start shooting right away, you can configure your custom Zebra Dry Plates right [here].

Wow , nice to see this experience, good luck with the business.

Marc

Thank you to let us ‘participate’ 👍😊