Zebra Lab Update: Tank Update, Golden Plates, Faster Emulsions?

The holidays are behind us, and while most people were winding down, things at the Zebra workshop were busier than ever. It’s the perfect moment to give you a big update on what we’ve been up to these past weeks.

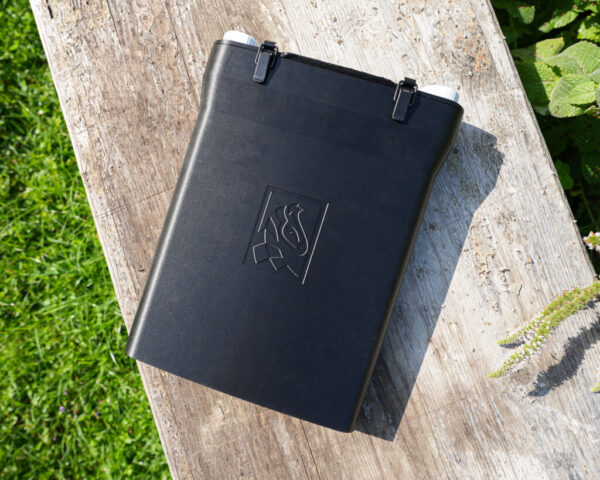

Daylight Processing Tanks – Redesigned and Ready

First things first: WOW. We’re still blown away by the incredible support of more than 500 backers who joined us on the Zebra Daylight Processing Tank campaign. Your encouragement and feedback are what keep this project alive and evolving. We listened closely to your ideas, and many of them shaped the improvements we’ve been working on since the campaign wrapped up.

Some things were clear winners: the innovative lid, the modular inserts, and the fast workflow, but we knew we could push further. Just like with our Zebra Sensitising Tanks, watertightness and durability had to be absolutely perfect.

During the campaign, our lid design relied on a single elastic band. It worked in theory but didn’t stand up to the lifetime of heavy use we wanted. So, we went back to the drawing board, tested countless variations, and are proud to share the final design:

✨ Stainless steel clasps instead of elastic bands. They secure the lid evenly and tightly, making the tank 100% watertight and light-tight even under extreme shaking.

✨ A reinforced body that stays rock solid even when filled to the brim.

✨ Fast + safe workflow with the dual-hole lid for quick filling and draining while keeping everything dark inside.

We tested it hardest with the 8×10 tank (because bigger always means tougher challenges), and it passed every trial like a boss. 💪The modular film adapters are next on the fine-tuning list, and production of over 550 tanks is about to begin in the coming days. Our workshop is going to be overflowing with tanks, and we can’t wait to get them into your hands!

A New Machine in the Darkroom

Another huge step for us this summer: we installed a custom-built dry plate coating machine in the darkroom. This has been the single largest investment in our workshop to date, and it’s already transforming how we work. I still owe you a full update on it (and I promise that’s coming soon!), but here’s a little teaser: it’s precise, efficient, and opens the door for new emulsion development on a scale we couldn’t dream of before.

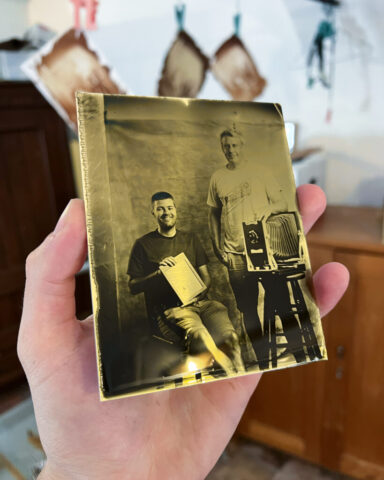

Introducing Zebra Golden Dry Plate Tintypes

We’ve also launched a completely new style of plates: Zebra Golden Dry Plate Tintypes. These are truly special. They let you create direct orotone plates without all the usual extra steps of drying, painting with gold, etc. We released a small first batch, and they sold out within hours. Backorders are already open, and we’re expecting new stock of golden tins to arrive very soon.

You can order the plates right HERE

More Projects Behind the Scenes

And of course, that’s just scratching the surface. Around the workshop, there are always many experiments running in parallel:

- Remodeling the darkroom (again!) because with the coating machine now running, we realized we’ll actually need another darkroom just for drying plates. 😅

- Testing a new UV exposure unit, which we’re really excited about.

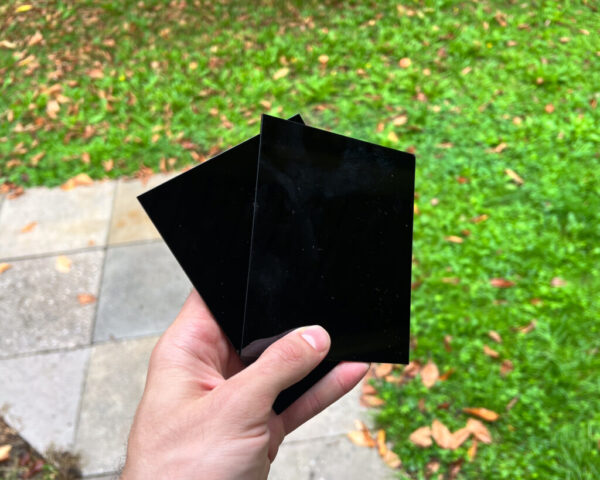

Investing in a large supply of black glass. This has been on our wishlist for a long time, and we finally made the leap. Our plan is to eventually replace black dry tin plates with black glass plates, which will also be offered as a raw material in the store for all dry and wet plate enthusiasts.

Pushing the Boundaries of Emulsions

We’re also working hard to bring a variety of new plates to the market with higher sensitivities and speeds. It’s no secret that right now I use about 10 liters of emulsion every week just to keep up with dry plate demand. Scaling up to larger batches of 50 liters or more is no small feat. Imagine throwing $5000 worth of silver nitrate into the bin if something goes wrong! 😅

This branch of production is still developing step by step, but we’re already excited for the future. Larger-scale emulsion making will allow us to experiment more freely and, most importantly, bring you new plate options that open up fresh creative possibilities.

Looking Ahead

So, while summer has been full of sunshine outside, the Zebra workshop has been glowing in its own way with new machines, new plates, and lots of tanks being built. We can’t wait to share even more updates soon and, most importantly, to get these tools into your hands so you can create with them.

Thank you, as always, for being part of this journey. The future of plate photography is being built piece by piece, right here in our little workshop.

Looking forward to the new developments and I am happy to see the growth in your enterprise. I am now shooting tintypes more often than film. Your work has made this change possible for my art.