History in the Making: The First Dry Plate Coating Machine in Nearly 100 Years

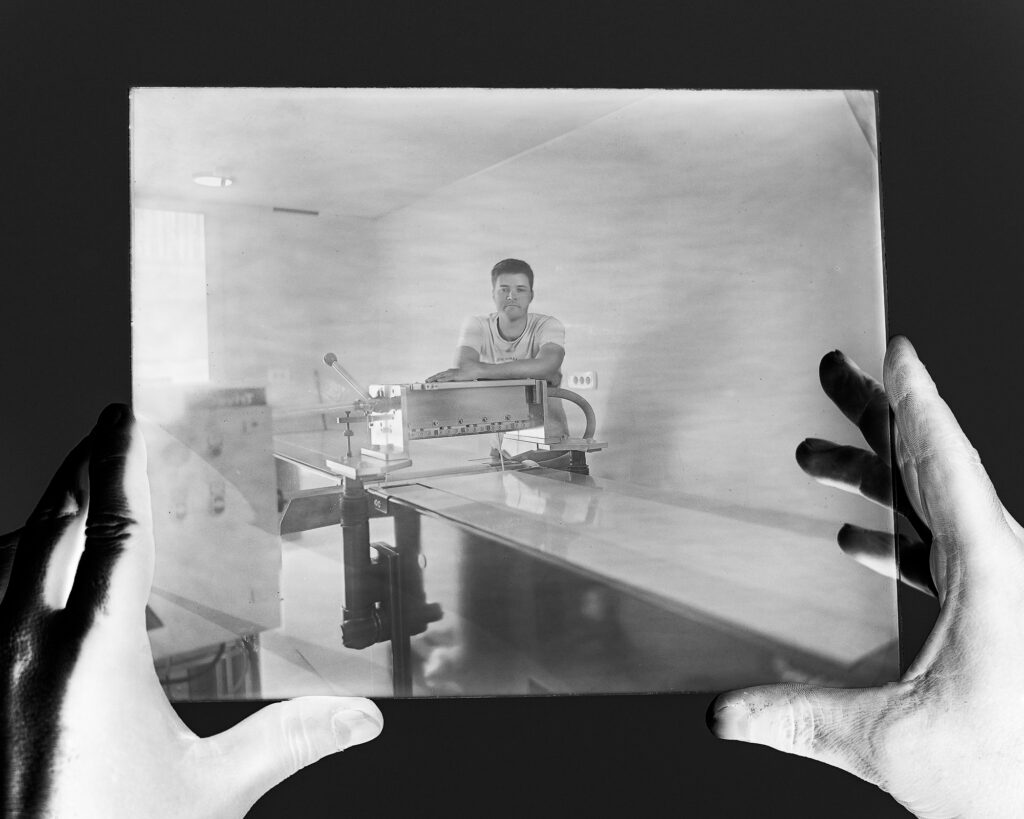

After months of development, numerous Zoom calls, and much anticipation, the Zebra Emulsion Coating Machine has finally found its home in our new darkroom.

How many film or plate coating machines do you think have been built and installed in the last 50 years? Not many, I reckon, and that makes this occasion even more special. We have worked incredibly hard over the past five years building our business. From my team producing the equipment, to me pouring tens of thousands of plates, the journey really shows how much passion goes into everything we do.

If we look at the history of photography, every step of progress has been driven by innovation. From camera builders to material producers, the common goal has always been to create products that serve photographers in making the most realistic recordings of the world possible. I had the same goal from day one when I started making Zebra Dry Plates.

Creating a passable emulsion coating is relatively easy, but creating a truly perfect one, thin, even, and completely free of bubbles and dust, is another story entirely. The syringe coating technique that I now teach in my workshops was developed and perfected by me over the last seven years. In that time, I have hand-coated at least 60,000 plates. Making a machine that can replace the hands in such a specialized and complex process is much harder than one might think. Emulsion coating requires tight control of many variables: temperature, flow, cleanliness, and much more.

How Zebra Plates Were Made Until Now

I still remember a few years ago when I filmed a YouTube video complaining about my back pain. At that time, Zebra Dry Plates were made entirely by hand, from grinding the edges, to cleaning, pouring the emulsion, and wrapping the finished plates. I have always believed in the “no pain, no gain” philosophy, but the truth was that my body was really struggling.

Preparing a single box of ten 4×5 plates took at least half an hour of standing work, and it left my back in pain. That pain, however, motivated me to find better and more efficient ways of making dry plates, and so the optimization process began.

The first step was a grinding machine, which sped up the edge grinding considerably and helped my back recover. Then came a household dishwasher for cleaning. After some trial and error, I managed to get it working, and later, when the budget allowed, we invested in a professional restaurant-grade dishwasher that produced even better results in a fraction of the time.With machines gradually taking over hours of the most repetitive labor, I was left mainly with the coating process. But as orders increased, even coating alone began consuming two to three full workdays each week. It became overwhelming, and to be honest, too much. I no longer had time to properly run the business, bring new ideas to life, or spend the quality time with my family that I wanted. That is when we knew our main company goal had to be the mechanization of the coating process. Here is a nice Video we have made on our current process from start to finish to make a single box of 4×5 plates!

Early Prototypes and Lessons Learned

As makers of many trades at Zebra, of course we first tried to build some prototypes ourselves. We experimented with spin coating, roller coating, spray coating, and even a homemade conveyor belt. Almost all of them failed miserably, but each failure taught us something important.

The main lesson was clear: emulsion coating is such a delicate operation that a quick homemade test machine would never perform well enough. The machine had to be designed and built properly from the ground up to deliver the results we required. At least by then, we also knew which approaches were not going to work, which gave us clearer direction.

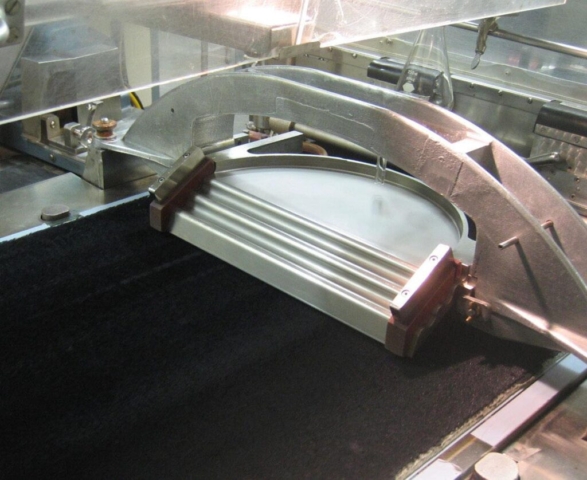

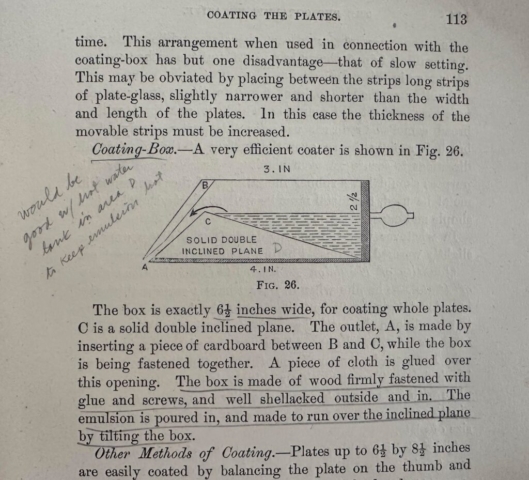

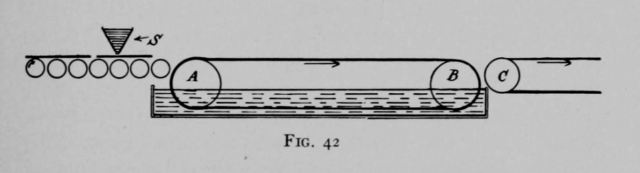

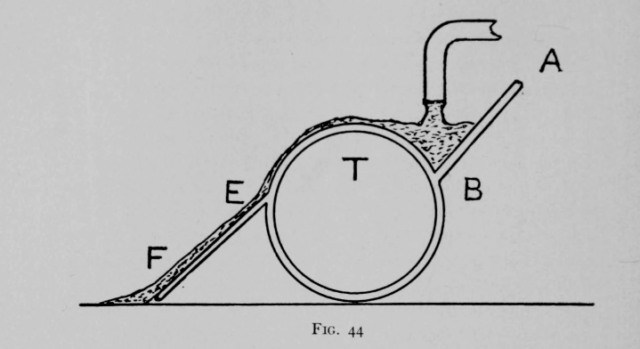

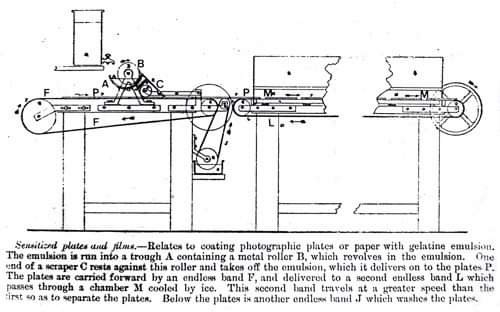

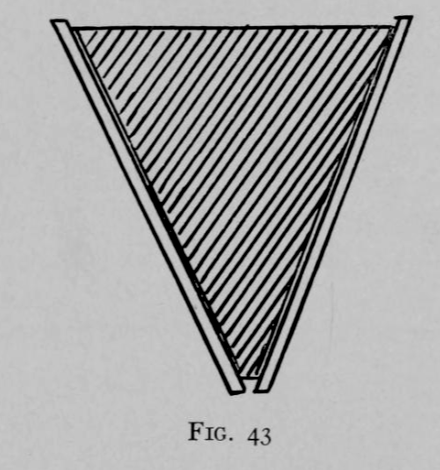

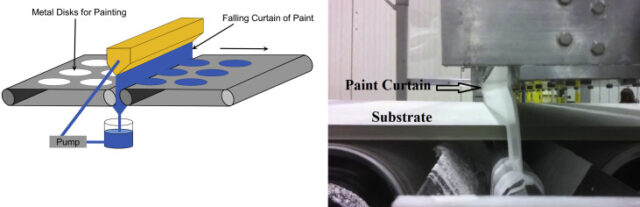

If you look through old books, you can find many patents for emulsion coating devices, but most of them were just prototypes or small-scale ideas tested on a few plates. Thanks to Mark Osterman and his generous sharing of knowledge and archives, we came across a photo he once shared of a brass coating head used by Kodak back in the day. It worked on the principle of a curtain coater. Seeing that part in physical form reassured us that this principle must have worked historically, and perhaps it was the way forward.

We also studied the coating heads Kodak still uses today for their films, which follow the same principle. Clearly, this was the direction we needed to take.

Finding the Right Manufacturer

Curtain coaters are still used widely across industries today for applying resins, UV protection layers, and similar materials. However, we quickly realized that adapting one of those machines for photographic emulsion would not be cheap. Standard curtain coaters were unsuitable for our needs because the emulsion must be heated consistently throughout the entire machine, and the level of precision required is far greater than in other applications.

We started researching potential manufacturers and were lucky enough to find one here in Europe. This turned out to be an excellent choice because we could visit the factory, receive samples, and fine-tune all the small details before committing.

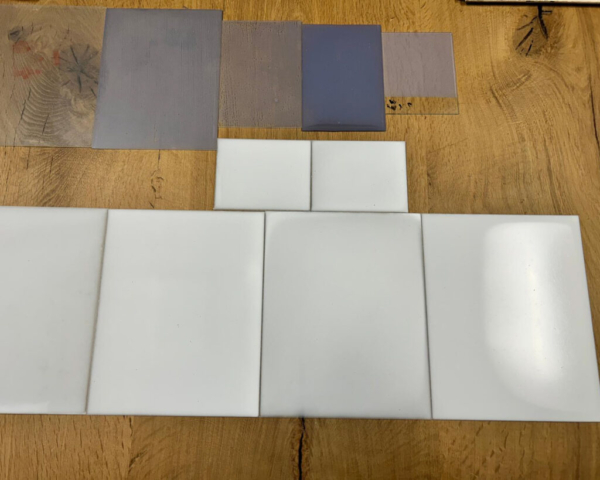

The machine was built and refined over the course of six months, with very promising test results arriving at our doorstep. For those early tests, we used a mock emulsion consisting of 10–12% gelatin (Bloom 250) mixed with a concentrated white water-based pigment, which allowed us to evaluate the thickness and evenness of the coating.

Arrival of the Monster

As you know, we have been documenting the construction of our new 30 m² darkroom here on the blog for the past year. The main reason for building it was to create enough space for this machine, which is 4 meters long, 2 meters wide, and weighs over 2 tons.

The machine was ready to ship in early July, but we still had a few final touches to finish in the darkroom, so delivery was delayed until the 9th of July. Even then, complications arose. As I mentioned, the machine is extremely heavy and large, and our workshop is in a small village about 10 minutes from Slovenia’s capital, Ljubljana. Access is tight, especially for big trucks.

On top of that, the entrance to the property was too small for a forklift to maneuver the machine inside, since it could only be loaded lengthwise. We had to come up with a new plan. Thanks to the cooperation of the manufacturer and the kindness of other Slovenian business owners, we managed to reroute the machine to a different location nearby. There it was unloaded from the truck, and the following day, it was placed on a car transporter and finally brought to our workshop.

With the big doors of the new darkroom opened, neighbors and the Zebra team gathered to help push the machine inside. We broke a tile or two in the process, but we like to think of that as good luck.

Of course, it quickly became clear that 30 m² would not be enough. We are already planning to expand the darkroom to 50 m².

Looking Ahead

Now that the machine is finally installed, we are full of excitement for the future. With coating largely automated, I will be able to shift my energy to other fields such as:

- improving and creating new emulsions

- designing new analog photography tools

- hosting workshops

- restarting my YouTube channel

- and most importantly, being there for my young family.

This milestone is not just a personal one, but also significant for the entire analog photography community. We are standing on the verge of producing the first machine-coated dry plates the world has seen in nearly a century.

Thank you!

I want to sincerely thank every one of you for supporting us on this journey and helping us keep this craft alive. None of this would have been possible without you.

In the following blog posts, we will put the Zebra Emulsion Coating Machine to the test and produce the first proper machine-coated dry plates. I suppose the world has not seen anything like this in about 100 years. Subscribe to the blog to follow the story further and witness this historic moment with us.

Bravo,

Industry and consistent effort. applied unstintingly.

I wish you all success.

Best,

Elliot

Devon, UK

Thank you!

I find this fascinating. I have just taken receipt of a fully working Houghton’s Triple Victo half plate field camera with a serviced and working Thornton Pickard shutter. I will shortly be ordering plates from you. I love the fact that you publish full manuals for usage, processing etc.

Thank you! We are looking forward to brung your camera back to life!

Nejc