Retouching Glass Plate Negatives & Dry Plate Lecture at University of Udine

Why Sharing Dry Plate Knowledge Matters

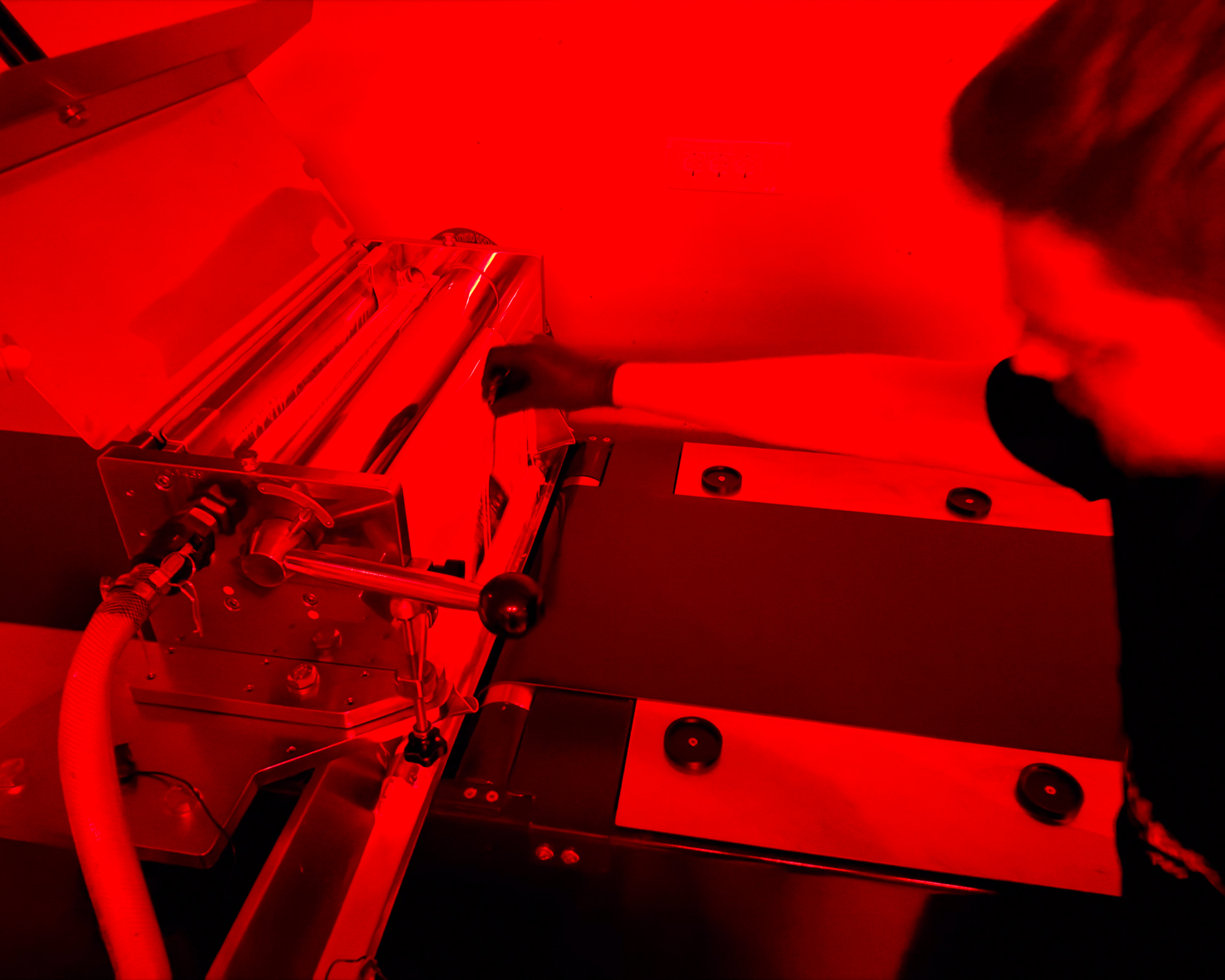

Not long ago, I was invited by the Fotonomia Association to visit the University of Udine and give a class on making dry plates. It felt especially meaningful, because in the past few years I have been deeply immersed in building the business and rarely had the chance to travel and share dry plate photography through in person classes. Most of my energy went into private workshops in Slovenia, creating videos, writing blogs, developing user manuals, and refining the tools themselves.

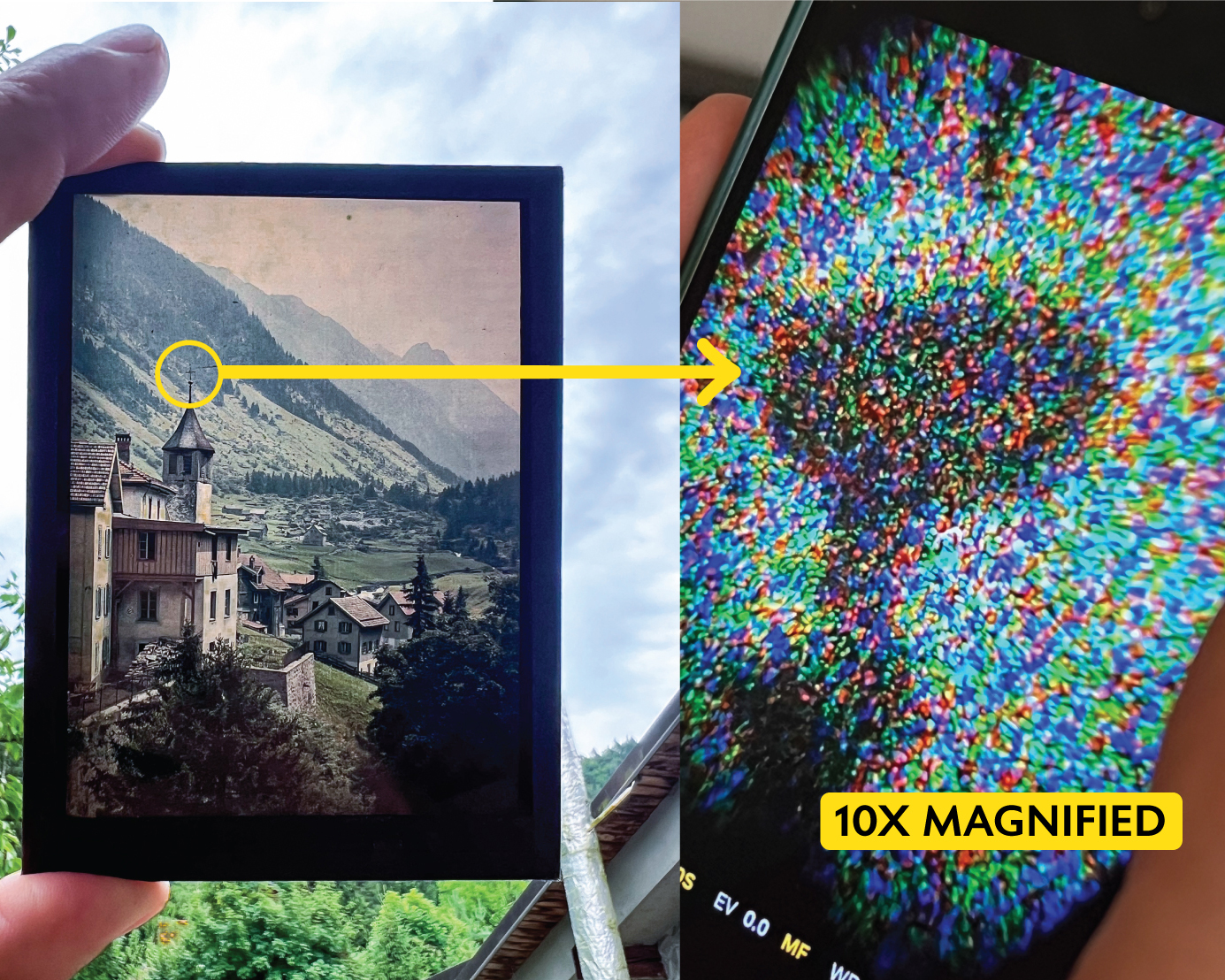

For me, dry plate photography is not just a technique. It is a responsibility to...