After Half a Century, Machine Coated Dry Plates Are Back

First Machine Coated Dry Plates After More Than 50 Years

Dry plates once stood at the heart of photography, coated in massive industrial facilities operated by companies like Ilford and Kodak. But in the 1970s, as the world shifted fully to flexible film, the last machine coated dry plates rolled off those production lines. The machines were shut down, dismantled, and never built again.

From that moment on, the survival of the Dry Plate process depended entirely on the few photographers and craftsmen who continued to coat plates by hand.

I eventually became one of them.

Over the last seven years, I have hand coated more than 100,000 glass plates of every size imaginable. As demand grew, so did the hours spent in the darkroom, often three full days a week just pouring emulsion, drying plates, and trying to keep up. Despite the long days, I loved it. Watching photographers experience the magic of dry plates made every hour worth it. There is something incredibly rewarding about creating a material that brings joy, preserves a historic craft, and inspires creativity.

However, spending so much time hand coating came at a price. In the beginning I produced a few hundred plates per month, but in the last three years I essentially became the machine. Orders kept coming in, and inside me there were many ideas waiting to be brought to life that I simply could not find the time for. I dreamed of making plates with different sensitivities, cyanotypes on glass, holographic plates, Autochromes, and much more.

The Journey Toward Mechanization

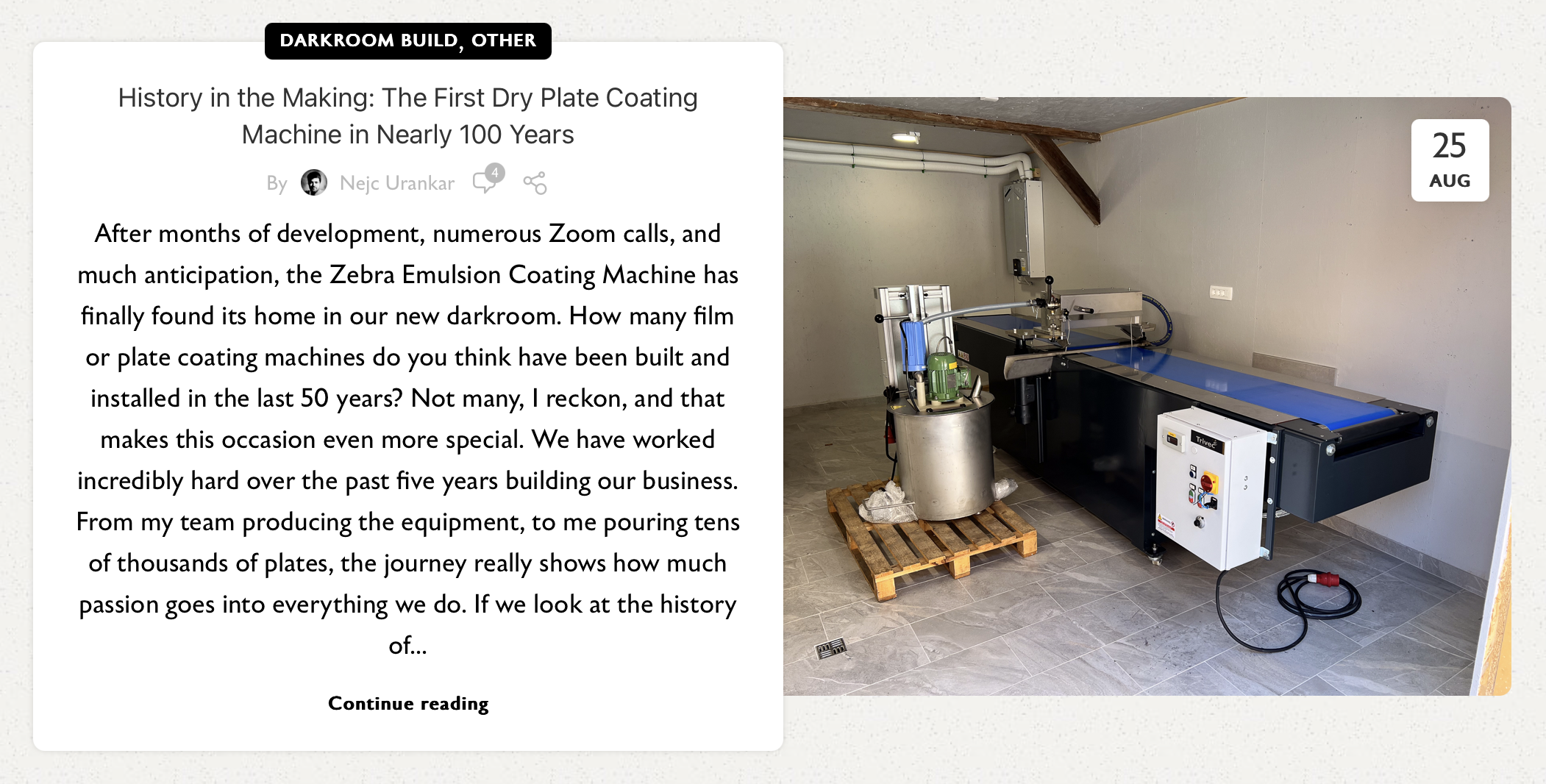

For the last two years we have been open about our efforts to mechanize the coating process. In a previous blog I shared the different paths, experiments, and dead ends we had to go through. Today I am incredibly excited to confirm that last week we coated the first larger batch of the new generation of Zebra Dry Plates. These are the first machine coated dry plates produced in more than half a century.

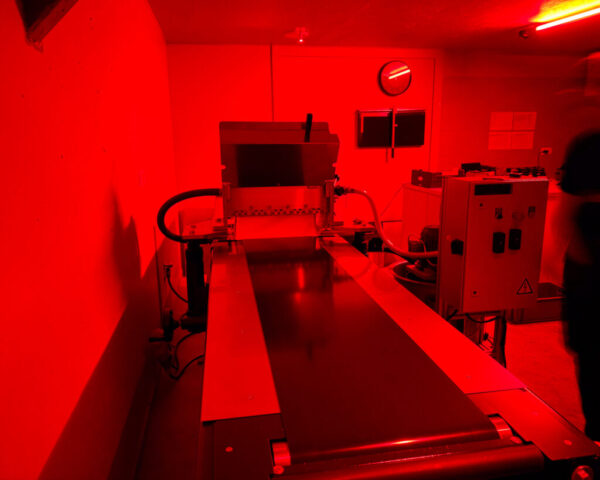

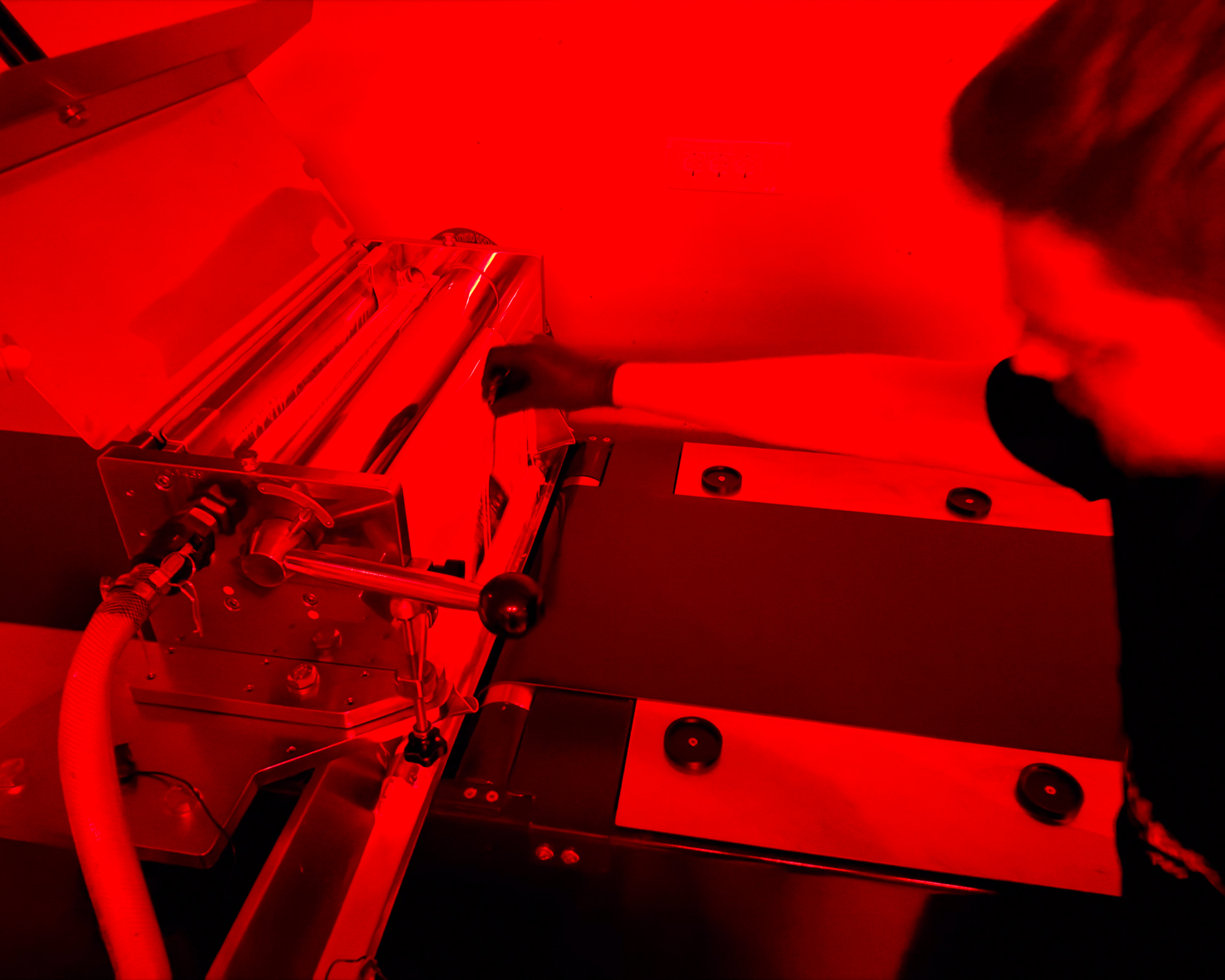

The plates are coated with laminar flow, the same method used in the production of modern 35mm film. This coating principle gives full control of emulsion temperature, plate transport speed, curtain thickness, and flow stability. As a result, we have precise and repeatable control over the final emulsion layer.

A few technical notes on laminar flow are worth mentioning. Laminar flow creates a perfectly smooth and non turbulent sheet of emulsion that falls uniformly across the moving substrate. The method is extremely sensitive to viscosity, temperature, suspension stability, and environmental conditions. This technology replaced older roller and dip coating systems in film factories because it offers superior uniformity and predictable thickness control. For dry plates this represents a major leap forward and reconnects the medium with its original industrial quality standards.

A Completely New Production Workflow

The machine changes everything. It solves long standing problems but also introduced new challenges. Hand coated plates could be dried in a small cabinet. Machine coated plates needed a much larger solution, so we converted an entire room into a drying chamber with hundreds of evenly spaced shelves to allow controlled airflow and stable drying conditions.

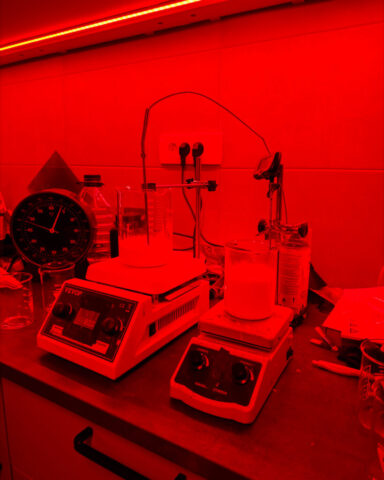

Scaling up the emulsion volume introduced new technical considerations. The machine requires nearly 15 liters of emulsion to keep the system circulating. This meant we needed an efficient way to recover and store unused emulsion after coating. Large batch emulsion preparation demands strict control of gelatin hydration, bloom strength, pH, temperature stability, and filtration. These were challenges that never appeared when coating by hand in small batches.

Our first two runs were not successful. We needed to become familiar with operating the machine, adjusting flow, pressure, temperature, and curtain thickness. The biggest issue was microscopic bubbles forming on the coated surfaces. After several mechanical and procedural adjustments, the problem was completely eliminated.

At one point we even managed to coat the emulsion so thinly that simply holding a plate from below caused faint palm impressions from the warmth of the hand. It shows how incredibly sensitive and powerful this system is when tuned correctly.

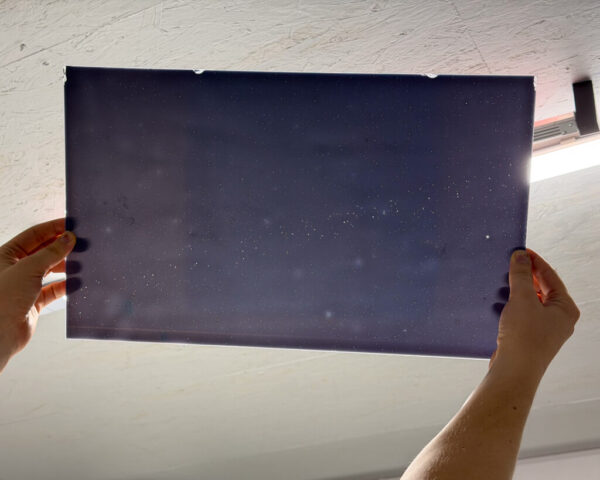

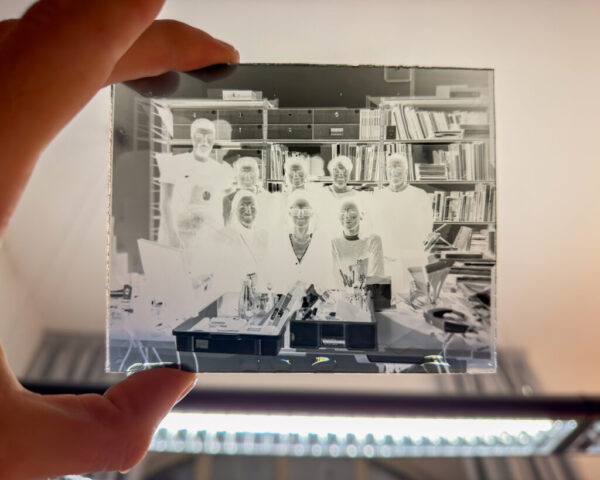

The third run produced flawless plates, and I am excited to share the first glimpses of the results.

Machine Coated vs Hand Coated Plates

Hand coated plates have a beauty of their own. The look and character of each plate can be unique. My personal aim, however, has always been to create perfectly even and consistent dry plates because that has been the goal since the invention of the medium. Ironically, we spent two years and significant resources trying to match the quality I achieved by hand. Not only did we match it, we surpassed it.

This achievement brings dry plate photography back in line with its industrial roots. Historically, dry plates reached their golden age precisely because machines produced consistent and reliable materials. Returning to machine coating means modern photographers can access high precision glass plates again, something the community has not seen in decades.

SUPERB QUALITY

The emulsion layer on the new generation of Zebra Dry Plates is thin and perfectly even across the entire surface. With more efficient production, we can now apply stricter quality control. Plates with imperfections such as empty spots, chips, or scratches will be separated and offered at a lower value for testing or for those who enjoy a more unique look.

CONSISTENCY

Consistency from plate to plate and, more importantly, from batch to batch is one of the biggest advantages of machine coating. This is crucial for creating predictable results. It is especially important for dry plate tintypes or reverse developed positives, where emulsion thickness has a major impact on contrast and tonal behavior. Machine coating allows us to offer long term batch availability, something simply impossible with hand coating.

Batch consistency also benefits alternative process printers, educators, researchers, and scientific users. Predictable density, speed, and contrast translate directly into stable exposure and development times.

PLATES OF DIFFERENT SENSITIVITIES?!

Now that production is more efficient, I can finally devote more time to developing new emulsions. This has always been a dream. In recent weeks we have already made major progress on higher ISO plates, orthocromatic plates, and even panchromatic plates. Panchromatic emulsions are one of the most important steps toward creating functional Autochrome style color plates.

Next up are black glass plates, expected to be available very soon. These may replace our current dry plate tintypes as the primary direct positive option. Tin plates are lightweight but inconsistent from batch to batch. Black glass plates offer the same high precision coating quality as our standard plates. We will still offer hand coated tintypes in smaller batches for those who love the aesthetic.

We Need Your Opinion

Which option should become our main direct positive material?

🔘 Black Glass Dry Plates

Beautiful deep black background

Superior consistency

High coating precision

Perfect for professional results

🔘 Dry Plate Tintypes (Current Option)

Lightweight and traditional

Vintage aesthetic

More affordable

Slightly unpredictable character

Tell us your choice in the comments or vote in our Instagram or Facebook poll.

DIRECT POSITIVES ON GLASS?

Yes, this is something we have been dreaming about for years. Being able to reverse process dry plates into direct positives was impossible before because hand coated layers were too thick and too uneven. Machine coating allows full control of the layer thickness. We can now create thin emulsions that reverse develop reliably, similar to commercial films, while offering the stunning resolution that only glass can provide.

This also brings us closer to creating true Autochrome style color plates in the future.

NO MORE HAND COATED PLATES?

Yes, machine coated plates will become the main Zebra Dry Plate lineup. However, we will still offer hand coated plates on request for those who want the artisan look and charm of hand poured emulsion.

Now I will finally have more time to visit fairs, hold lectures, and meet the Zebra Family in person. I want to see how you use our products, what you love, and what you wish existed. This helps us design and develop the tools you truly need. I recently returned from a lecture in Udine, Italy where the excitement of the participants reminded me why this craft matters. Watching emulsion being mixed, coated, exposed, and developed in just a few hours always brings magic to the room. It is moments like these that keep Zebra moving forward.

The analog revival is not nostalgia. It is living craft. Your support, creativity, and passion made this breakthrough possible. We are excited to bring machine coated dry plates back to the world, and this is only the beginning.

A Final Note: Black Friday Sale Is Live

Before finishing this update I want to share one more piece of news. Our Black Friday Sale is now live, and it is one of the rare times of the year when you can get Zebra products at a reduced price. If you have been thinking about expanding your dry plate setup, stocking up on essentials, or trying something new, this is a great opportunity.

Your support during moments like this truly helps us push forward with development and innovations such as the new machine coated dry plates. It helps keep this craft alive and ensures we can bring even more analog tools to the community.

Thank you for being part of this historic moment and for standing with us as we take dry plate photography into an exciting new era.