Maximising Your Darkroom Space: Darkroom Sink Installation, Ventilation and LED Safelights

It has been a whirlwind few weeks here at the Zebra workshop, packed with exciting developments and challenging projects. Between finalizing the new darkroom and launching our second Kickstarter campaign, it’s been intense, rewarding, and truly inspiring.

Kickstarter Success Exceeding Expectations

First off, a heartfelt thanks to our incredible community. Our second Kickstarter campaign for the Zebra Daylight Processing Tanks has been a resounding success, reaching over 800% funding with nearly 400 photographers backing the project. This overwhelming support highlights the genuine need for versatile, user-friendly analog photography solutions. Our tanks offer modular processing options for various formats, including popular sizes like 4×5, 5×7, and 8×10 inches, as well as European standards like 9×12 cm and 13×18 cm. Importantly, the tanks can process both film and glass plates. If you haven’t seen the project yet, here’s your chance!

Darkroom Progress: The Final Sprint

Parallel to the Kickstarter excitement, the final stages of our new darkroom build have demanded almost every free minute. The arrival of the Zebra Plate Coating Machine necessitated a fully functional and meticulously prepared space. We have started working on it early this year constructing zebra workshop extension under a 150yo wooden hay rack. Looking back now its incredible to see where it has all started! A few months and blisters later let see where we are at…

Custom Cabinets, Counters & the Perfect Rolling Workbench

A significant milestone recently was completing the furniture setup. Custom-built cabinets and durable countertops now fill the space, offering plenty of organized storage for trays, chemicals, and photographic tools. After years of operating out of a tiny, cramped shipping-container darkroom, having a thoughtfully organized and spacious area is an absolute dream.

But my favorite addition by far is our newly built rolling island workbench, specially designed as the centerpiece for workshops, demonstrations, and tutorials. Mounted on sturdy wheels (lockable for stability), this versatile bench can be easily repositioned within the darkroom to accommodate various workflow needs. It features a robust wooden countertop for ample workspace and shelves beneath, providing convenient storage for commonly used equipment. It’s already become one of those indispensable tools leaving me wondering, “Why didn’t I build this sooner?”

Moving the home made – Darkroom Sink

The darkroom itself is completely windowless, just as it should be. Since we’ll have a proper ventilation system, there’s no need for natural light—and no risk of light leaks ruining A major task involved relocating my custom-built sink from the original shipping container darkroom. Crafted from wooden panels sealed with multiple epoxy layers, this 2.5-meter long sink has stood the test of time through heavy daily use. Carefully engineered to fit precisely within my old setup, extracting this beast presented a significant logistical puzzle. At one stage, I seriously contemplated cutting through a wall to free it!

Thankfully, after some careful maneuvering and generous assistance from my father-in-law, we successfully transplanted the sink onto new cabinets specifically installed for this purpose. I enhanced its integration with custom-sized, dark-gray finishing boards, blending seamlessly into the darkroom’s aesthetic. Plumbing was completed professionally, ensuring a leak-free, reliable workspace. For those interested in making a similar sink, check out my detailed blog post:

[Link to original sink-building blog post]

Darkroom Safelights – Mastering the Light Setup

Proper lighting is absolutely critical in any photographic darkroom. Initially, I experimented with standard LED fixtures covered in rubylith foil to produce safelight conditions. However, even fully dimmed, these setups were too intense, particularly for sensitive processes like plate preparation.

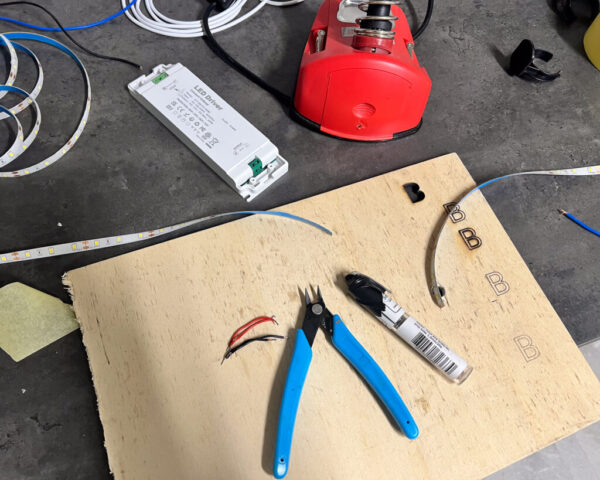

To overcome this, I upgraded to specialised red safelights from Fotoimpex, strategically placed over high-use areas and hallways. They are small and don’t emit much light but like said most of the times there is a worry of too much! For anyone interested here is the LINK. Our main work area uses a Heiland safelight bar, a powerful unit that required additional tweaking tho. To avoid fogging sensitive materials due to extreme brightness, I designed and 3D-printed a custom spacer, directing the bar’s light upwards to achieve optimal diffusion (LINK) For the sink workspace, simple red LED strips from an online store provided the perfect balance intensity without the need for additional filtration. Additionally, the switch controlling the white lights is purposefully placed high at 2.2 meters to prevent accidental exposure an easy yet highly effective safeguard. Also all of our main Safelights are dimmable to the point where you can barely see anything. This is crucial

Darkroom ventilation Critical for Safety and Comfort

Our windowless darkroom required thoughtful ventilation planning. Given the 35m² workspace (around 70m³ volume), we selected the Pichler LG100 ventilation unit a high-quality heat exchange system that effectively refreshes and filters the air. Initially planning to contract this out, I decided to tackle the installation myself, saving considerably and ensuring meticulous attention to detail.

Basic installation involved cutting precise wall holes, routing the air hoses, mounting the unit securely, and connecting it to power and an external control panel to prevent light contamination. However, for maximum effectiveness, the next step involves strategic placement of intake hoses over key areas like the sink and workstation counters, optimizing airflow to ensure both comfort and the health of users.

Looking Ahead Final Touches

With the Zebra Plate Coating Machine arriving imminently, a few critical tasks remain:

- Fine-tuning ventilation hose placement

- Detailed organization of gear and workspace

- Building huge drying cabinets to meet the Dry Plate coating capacities

We’re on the cusp of finishing things up, ready to significantly elevate our Plate Production capabilities.

Thanks for Being on This Journey

None of this would be possible without you. Whether you’re using Zebra Plates, backing our Kickstarter, or simply sharing your photos with the world—you’re helping this community grow.

I’m so excited to share the final reveal with you soon—and maybe even host some of you here one day.

Until then, stay inspired and keep shooting.

Nejc